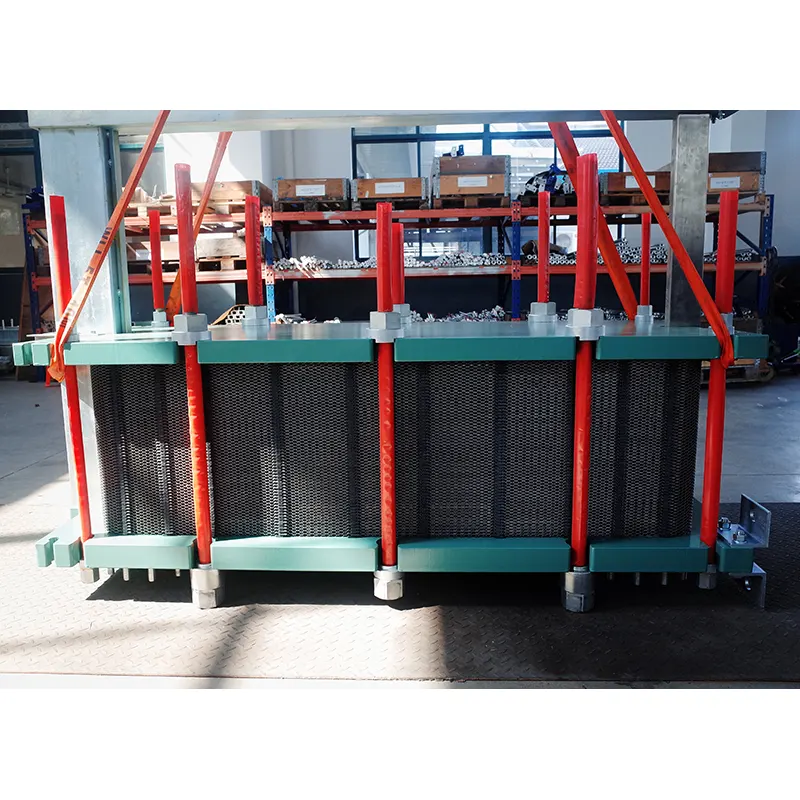

Quod productum structuram Daniel de Daethacable laminam calor exchanger

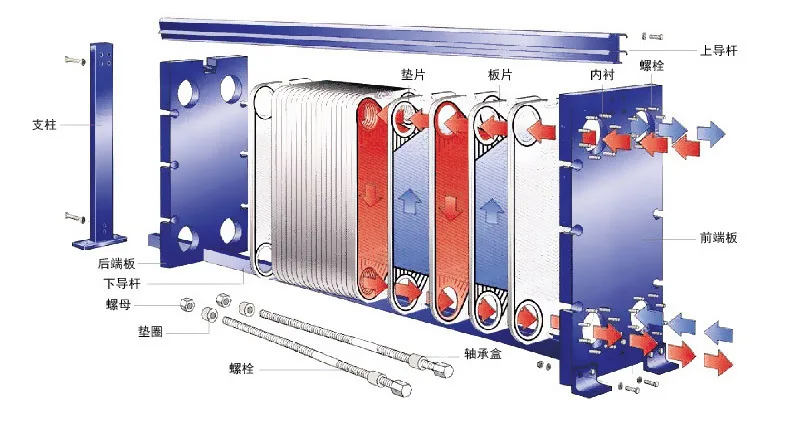

Components de laminam calor exchanger

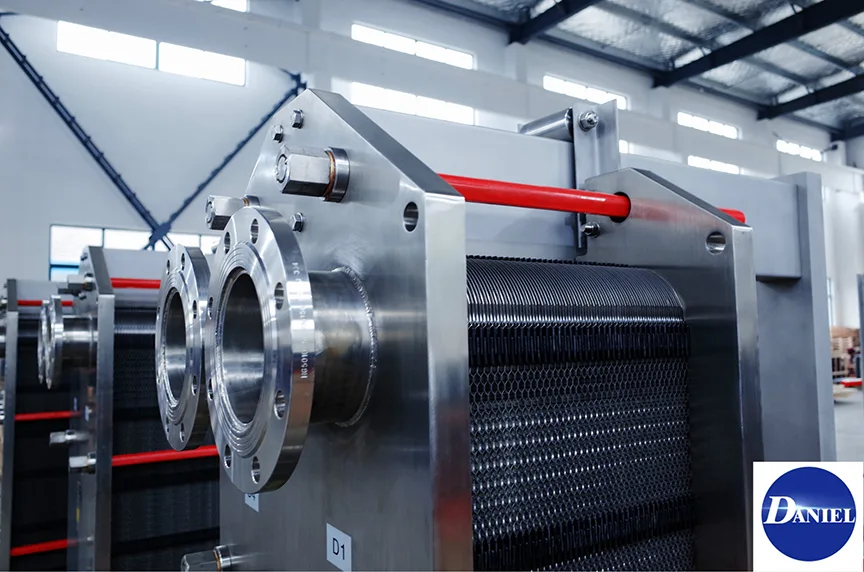

Foro et applicationem

Nam longo tempore, Jiangyin Daniel Thomas est committitur ad providing summus qualitas laminam calor de Customers in PETROLEUM, eget, Industrial, cibum et potum, potentiam, Metallurgy in multis terris et regionibus. Currently, magis quam 20,000 laminam æstus, sunt operating bene in variis industrias.

De commoda laminam calor deicit

Promovere fluxus liquidae inter laminas ad formare turbulentiam. Admitte metallum laminam ad aptet ad diversas pressuris. Et fluxus alveo de "Herringbone" parva forma laminam composito ex duobus adjacent laminis cum herringbone angulus differentia CLXXX gradus. Ergo multi anguli punctorum inter laminas, quae potest pervenire singulis 130mm ². Et fluxus alveo est pronus ad deformationem, habet relative altus pressura resistentia, et potest sustinere fortis pressura differentia. In eodem tempore, cum fluxus est tria dimensiva et turbulentia est relative intensior, calor transitus coefficiens est princeps.

|

Compactum |

In spatium occupatum laminam calor exighanger est de minimis inter omnes genera caloris exharchers ad praesens. Sub eadem calore commutationem condiciones, areæ area de laminam calor exchanger est solum 1/3 ad 1/4 de hoc de testa et fistulam calor exchanger, et non eget additional sustentacionem spatium cum disassembled.

|

|

Princeps calor translationem coefficientem |

Ex eo quod medium fluit in laminam coetus potest formare turbulentiam ad relative humilis reynolds numerus (re) et fouling est minus verisimile ad formare in lenis laminis, quod habet valde calor efficientiam. In generali aqua-ut-aqua calor commutationem, in calorem translationem coefficientem de laminam calor exchanger potest pervenire super 6000W / m² ² ℃, quod est III ad VIII temporibus altior quam de testa et tuba calor VIII.

|

|

High calor Recuperatio Rate |

Ob altum calorem translationem coefficientem, optimum fluxus Ratio characteres et omnino e converso fluxus, calor translatio temperatus differentia potest delectis nimis humilis. Ergo apta recuperatio humili gradu industria calor. Est oeconomice fieri ad consequi calor recuperatio rate de super XC% usura una laminam calor exchanger.

|

|

Magna Adaptability |

Et foldable laminam calor exchanger habet unice delectabile adaptability. Post installation, in metallum laminam coetus potest augeri vel minuatur obviam processus requisitionem expansion vel contractionem.

|

|

LUCRIDUS |

Ob eius parva fluxus alveo et minimam stagnantibus fluunt, potest satus cito, respondent statim cum imperium operationes mutare, et significantly reducere pondus in apparatu.

|

|

Convenient ad sustentationem |

In consilio et laminas ensures non sunt mortui angulis, ut eget purgatio potest ferri ex on-site sine disassembly. Nam laminam calorem delaticis, possunt etiam facile aperuit mechanica elit.

|

Jiangyin Daniel Cooler Co., Ltd. (Daniel Cooler) was founded in 2004. It is a heat exchanger manufacturer that produces detachable plate heat exchangers (PHE), heat exchanger gaskets (PHEGASKET), heat exchanger plates (PHEPLATE) and provides plate heat exchanger maintenance services (PHEMAINTENANCE).

Jiangyin Daniel frigidior Thracam habet consilio et productio technology et professionalem calor exchanger scientia. Jiangyin Daniel frigidior Thracam est committitur ad providing qualis laminam calor de Customers in PETROLEUM, eget, Industrial, cibum et potum, electricity, metallgy in multis terris et regiones.

Special laminam evaporator condensers et rubber gaskets potest disposito et fabricari secundum mos necessitates

Plate heat exchanger rubber strip models: M3, M6B, M6M, M6MX-L, M6MX-R, M10B, M10M, M15B, M15Blip, MK15BW, M15M, M20M, MX25B, MX25M, M30, MA30M, MA30W, EC500, AM20, P31-HBM, AK20, C10, Clip6, Clip8h, Am30, MX25, EC350, TL6B, TL10B, TS20M, TS6M, Am30, P22, P26, P31, T20M, A10B, T010B, T200, Clip6, Clip10, T200 Ax30bw, JWP26, JWP36, EC50, EC150, EC350, EC500.

Sugar industry, Metallurgical industry Heat exchanger rubber gasket, sealing gasket EC50, EC150, EC350, EC500, EC500-WTEL, EC500-WTFE, EC500-ETFC, EC500-TFR, EC50-WTEL, EC50-WTFEEC50-ETFC, EC50-TFR, EC350-WTEL, EC350-WTFE, EC350, ETFC, EC350-TFR,

Plate heat exchanger gasket model: T4, H17, N35, N25, SR2, N50, A055, J060, M92 (adhesive), J092, A085, J107, Q080, K34, K55, K71 (adhesive), P105, M60, P190, U2, E201, SR3, Q030, Q055, J185, SR6, H12, SR1, RS3

Plate calor exchanger Gasket exempla: VT4, VT8, VT10, VT20, VT20, N406, VT40, VT2508, NT1006, NT1008, NT100M B, NT5X, NT100T, NT100M, NT1000, NT100T, NT150L, VT405, NT250s, NT250L Vicarb

Plate calor exchanger Gasket exempla: V10, V20 (button type), V20 (f crustulum) V85, v85, v85d, v100a, v170, v85d, v100a, V17, V85D, V100, V17, V85D, V100, V280

Plate heat exchanger rubber pad model: GX-12, GX-12P1, GX-018, GX-26, GC-26, GX42, GC42, GC-30PI, GC-60PI, GX-51, GC-51, GX-60, GX-100, GX-180,

Plate calor exchanger Flexilis codex Model: Sigma9, Sigma26, Sigma27, Sigma37, Sigma66, Sigma26, Sigma114, Sigma7, Sigma X29, Sigma M37, Sigma38, Sigma M66, Sigma CVII, Sigma M66, CVII Sigma, Sigma CVII Sigma, Sigma CVII Sigma, Sigma CVII, Sigma M66, Sigma CVII Sigma

Plate heat exchanger rubber sealing gasket model: S4, S7, S8, S9, S14, S15, S15FS, S21, S22, S30, S37, S39, S41, S43, S47, S50, S62, S65, S81, S83, S121

Plate heat exchanger sealing ring model: TL90PP, TL90SS, TL150PP, TL150SS, TL200PP, TL200SS, TL250PP, TL250SS, TL400SS, TL500PP, TL500SS, TL650PP, TL650SS, TL850PP, TL850SS

Plate heat exchanger gasket model: RX-70, LX50A, EX-15, EX-16, UX416, UX-01, UX-05, UX-20, UX-30, UX-40 can be designed and manufactured according to customer requirements

Special laminam calor exchanger laminis et rubber gaskets principalis exempla de laminam calor exchanger laminis et rubber gaskets:

I. Plate calor exchanger laminis. M3, M3 (N), M3X, M6-MFL, M6MD, M10 (MFML, MFGL, M10BD, M10BW), M10-BFGL, M15-(MFG, MFML, FFM, BFG), M15-MFGL, M15-BFML, M20-MFM, M20-MWFM, M20-FKMG, AM20-SFM, M30, MX25B, MX25M, AK20-FGL (E, F), A10 (B), A15, A15B, A15BW, A20, A20B, A3, A35, AX30, TS6, TS20, TL6, TL10, TL15, T20, C6, C8, C10. AC400. AC600, AV170, AV280.

2. Plate heat exchanger plates A055.AO85, CHF130, H12, H17, H17PA, H17DS, J060, J092, J107, J185, K34, K55, K71, K71PA, M60, M92, M185, M107, N35, N35DS, N35PA, N50, Q030D, Q055D, Q080D, R10, R10G, R14, R14S, R23, R40S, R5, R55, R66, SR2, SR3, SR9, SR14, BR1.06, BR034, BR028, BBL1.6TAF, BBL1.6BF, BR1.08CF? N35, N25, N50, AO55, H17;

3. Plate heat exchanger plates: GX-51, GX-013, BR013 (trough type), GX-108, GX-214, GX-26, GC-26, UFX-26= GX-26GX-26, GX-51, GX-100, GX-60, GX-180, GC-26, GC-51... Vicarb (method G): V10, V20, V45, V60, V85 ... Sondex: S14, S15, S15Fs, S21, S30, S41, S83 ... Hothaka, W.Schmidt ...... ..

IV. Plate calor exchanger laminis nt150l / NT10 / FA157 / FA158 / AF161 / FA184ng / FA184WG / FA192NG / FA192WG / VT10 / VT20 / vt2

V. BR Series laminam exchanger laminas produci in G BR Series BR005, Br01, Br03, Br05, Br08, Br13 ...

Applicationem Daniel Plate calor exchanger Gasket:

Navis Industry: Maxime propter refrigerationem, Jacket aqua refrigerationem, lubricating oleum refrigerationem, piston coolant cooperationem, tradenda oleum refrigerationem, grave cibus oleum prheheating, Diesel Preheating, aliud processus refrigerationem, pellentesque preheating, alius processus refrigerationem, cerei, etc.

Power industria, calor est maxime in aperto et clausa cycle aquam refrigerationem, transitum oleum refrigerationem, Turbine oleum refrigerationem, lubricating olei cooperationem, Piston et Turbine et engine coolant recuperatio, exhauriunt Gas et calor recuperatio, exhauriunt Gas, calor recuperatio, exhaurit

Heat exchangers are mainly used in the pharmaceutical industry for: drug sterilization, emulsion cooling, suspension heating, plasma heating, citric acid heating, infusion cooling, etc., steel industry heat exchangers are mainly used in the steel industry for mold/continuous casting machine coolant cooling, hydraulic oil/lubricating oil cooling, machine coolant cooling, electrolyte heating and Refrigerant, Fungi aqua / Pasce aqua / EMULSIO / CKING Plant Wastewater Refrigerant, fornacem / Electric J Support / ToOnt Cooling.

Calor de maxime usus est in HVAC industria: District calefactio, domesticis calida aqua, glacies adipiscing, assidue calefacit natandi lacus, calor sentinam cogitationes, calor recuperatio machinas, calidum aquam, etc.

Calor de maxime usus est in chemical industria: calefactio et refrigerationem processus media, oleum refrigerationem, electrolyte refrigerationem, degreasing humorem calefactio, phosphating liquidum refrigerationem, etc.